Plastic tabletop is the most affordable, but not at all second-rate option, because it is in many ways better than expensive tabletops made of wood and even stone. The main thing - to choose it correctly and know the rules of operation. In this article you will find 7 tips on choosing a kitchen worktop made of laminated chipboard, an overview of the pros and cons of the material, as well as recommendations for care.

Pros and cons, comparison with other materials

The plastic tabletop is a chipboard with a decorative and protective coating of melamine. Thanks to the digital printing method, the pattern of the decorative layer imitates natural textures, such as granite or wood. And the top layer can be smooth, dull or shagreen.

Pros:

- Low price (1000-4000 rubles. Per meter);

- Ease of care;

- Resistance of color to fading from UV rays;

- Relative heat resistance - plastic withstands short-term contact with hot dishes up to 180-230 degrees (depending on the thickness of the plastic layer);

- Resistance to rubbing with a brush and cleaning with the use of aggressive household chemicals;

- Resistance to moisture (subject to intact protective layer and closed ends);

- Ease of installation and dismantle;

- The variety of colors and textures (more than 150 color options, as well as the ability to choose a print yourself, buying a table top to order).

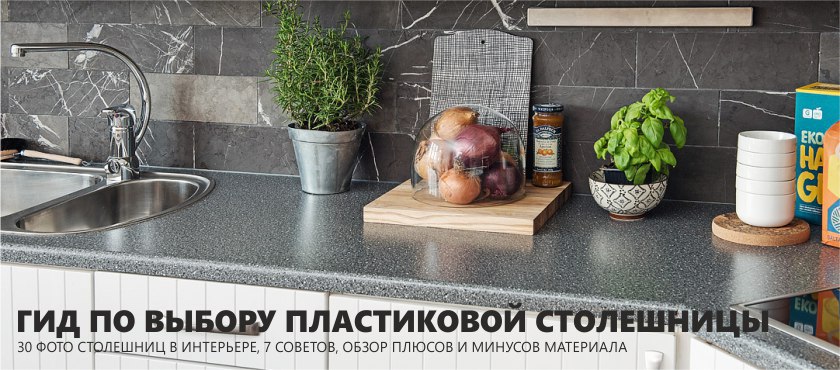

Below are examples of what a plastic tabletop can look like under a stone or wood in a kitchen interior.

Laminated chipboard top in stone

White plastic tabletop in the interior of the kitchen

However, there are drawbacks to the worktop from laminated chipboard, it is:

- The artificiality of the material, visible to the eye and to the touch;

- Toxicity with open ends (however, for the manufacture of countertops, as a rule, use particleboard class E1, which emits formaldehyde in small quantities);

- Plate swelling when moisture gets into areas with damaged plastic layer;

- The presence of visible seams (closed with special profiles), if the kitchen is angular as pictured below or longer than 3 meters.

If we compare LDSP with other popular materials only in terms of performance, it turns out that “plastic” is inferior only to agglomerate (composite material made of natural stone and polymers) and surely wins wood and natural stone (if you look at the table below from a mobile device, turn the screen in horizontal position):

| Tree | Agglomerate | A natural stone | Acrylic stone | Chipboard | |

|---|---|---|---|---|---|

| Scratch resistant | 2 | 3 | 2 | 1 | 2 |

| Pollution resistance | 2 | 3 | 2 | 3 | 3 |

| Resistance to cracking and chipping | 2 | 3 | 2 | 3 | 3 |

| Resistance to flame and high temperatures | 1 | 2 | 3 | 2 | 2 |

| Resistance to caustic acids | 1 | 3 | 2 | 3 | 2 |

| Moisture proof | 2 | 3 | 2 | 3 | 2 |

| Impact resistance | 2 | 3 | 1 | 2 | 2 |

| Color fastness | 2 | 3 | 1 | 3 | 3 |

| Total points | 14 | 23 | 15 | 18 | 19 |

* 3 - excellent, 2 - satisfactory, 1 - bad.

7 tips for the buyer

Tip 1. Choose a worktop with a seamless edge.

Previously, the ends of kitchen worktops made of laminated chipboard were covered with decorative edges, which were peculiar to peel off due to moisture and dirt getting into the seams.

Plastic worktop with melamine edge

Modern worktops most often (but not always) have seamless front ends wrapped with plastic using the postforming method. Sometimes a plastic coating reaches only the bottom edge of the end (the joint is treated with sealant), and sometimes it is wrapped on the back side. The latter option is preferable, since in this case the seam remains hidden and difficult to access for moisture and dirt, and in case of large leaks it has a drip pan (see photo below), which will not allow moisture to penetrate into the thickness of the slab. By the way, the drip tray is not present in all countertops, so we advise you to always check its availability.

Countertop postforming usually has a rounded edge

The drip tray is a groove in which in case of a leakage water will collect, not allowing moisture to penetrate into the thickness of the chipboard

- Worktop type postforming suitable only for kitchens with a right angle, and not curved. The edges of the rounded tops are covered with plastic, melamine and even aluminum edges. Most often, the edge is chosen in tune to the table top, but if you wish, you can make it contrast.

Tip 2. The thicker the plastic layer, the more reliable the material

The durability and durability of the tabletop mainly depends on the thickness of the plastic layer. Most often, domestic and Polish manufacturers make a layer of melamine with a thickness of 0.4-0.5 mm, and manufacturers of Germany and Italy - 0.8 mm. Such a protective coating does not burn through and does not deform from short-term contact with, say, a hot pan.

Tip 3. The thicker the chipboard, the more thoroughly it looks

Plastic countertops can be 2.8 cm thick, 3.8 cm thick and less often 4 cm thick. The thicker the slab, the finer it looks and the more it resembles a stone or wooden countertop. In addition, thick laminated chipboard allows you to stand on the floor bollards, for example, to tidy up the top kitchen cabinets.

- For a non-standard headset, you can order a more solid worktop, 6-10 cm thick or, conversely, thinner, up to 12 mm thick. However, the front edge of such a non-standard plate will be closed not by postforming technology, but by a usual edge.

Tip 4. Smooth semi-matt light-colored worktop less branded than dark, glossy and structural

When choosing a plastic tabletop in color, keep in mind that on a dark background the smallest contaminants will be very noticeable, for example, water droplets, dust, dirt, stains after cleaning, chips and grains. If you really want to install a dark tabletop, then we recommend choosing a slab with pronounced light blotches or veins, for example, with a granite texture as in the photo below or marble.

We also advise to avoid tabletops with a pronounced structure (for example, repeating the relief of wood), as well as with a glossy finish. The first option is harder to clean, and the second is prone to quickly get dirty with fingerprints.

Worktop made of laminated chipboard with a structure is somewhat harder to clean a smooth surface.

The glossy plastic tabletop is less prone to scratches, but it is more difficult to clean, since fingerprints are very noticeable on it.

Tip 5. Ideally, purchase a tabletop of increased depth.

The standard depth of the kitchen worktop is 60 cm, but ideally you should choose or order a slab of increased depth - 63-65 cm. So you will not “beat” with your feet on protruding furniture handles.

- Sometimes for the arrangement of the kitchen requires a tabletop even greater depth. For example, if you need to bypass the vent ledge or embed it in the window sill. In this case, it is worth looking for factories that produce slabs up to 120 cm in depth.

See also the material: Sizes of kitchen countertops made of laminated chipboard, solid, artificial and natural stone. What you need to know before buying?

Tip 6. Follow the rules of use and care.

- If possible, remove stains, especially liquids, as soon as possible with mild detergents and a cloth;

- To remove old stains, they must be treated with a cleaning agent and left soaked for a while or treated with a liquid detergent for cleaning and polishing furniture (except for glossy surfaces);

- Oily contaminants (oil, grease, wax, etc.) must be removed with organic solvents;

- Keep in mind that glossy countertops can not be treated with polishing agents, as well as with oils and wax-based products, otherwise the surface will no longer shine;

- Always use a cutting board to avoid scratches;

- Do not place hot pans or pots on the laminated countertop for more than 20 seconds. Utensils, just removed from the stove, and it is worth keeping away from the chipboard, because even the highest quality plastic will withstand contact with dishes with a temperature of 230-240 degrees, while red-hot dishes can reach 250 degrees.

Tip 7. Worktop should be combined with elements of the kitchen interior.

Most often, the kitchen countertop is matched to the apron or facades of the headset (see photo example below). Also to orient in the choice of colors and textures can be on the window sills, the floor, the countertop of the dining table.

Plastic top to match the headset

- The choice of kitchen countertops - the advantages and disadvantages of popular materials

- Wooden Counter Top Guide

- Color kitchen countertops - selection rules and tips

- Stone countertops in the kitchen - practicality and natural charm

- Self-installation of kitchen countertops - from cutting to insertion sink

- Kitchens with MDF fronts - 10 tips for the buyer

- Plastic apron - information for customers

(Rate the material! Already voted:44 average rating: 4,59 from 5)

(Rate the material! Already voted:44 average rating: 4,59 from 5)

Formaldehyde????? To be terrified It's good that I have a tabletop made of artificial stone Antarried, now I love it even more)

Good thing I'm not as stupid as Rita.

Stone processing production.

We can offer you products from natural stone and quartz agglomerate. Let's make table-tops, window sills, ladders, fireplaces, a panel from onyx and many other things what your imagination and the budget of the customer are capable of. Short terms and reasonable prices. We count on long-term cooperation. We are ready to calculate your order. 8 (812) 372-69-72

Mikhail Loginov